AE-MP series

Raypa

AE-MP series

Media preparation, sterilization and dispensing of high quality culture media with outstanding batch to batch reproducibility.

Information

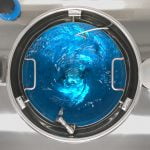

AE-MP streamlines the operative workflow for microbiology and plant tissue culture laboratories. In one single device it is integrated the preparation, sterilization and dispensation of high quality culture media with outstanding batch to batch reproducibility. AE-MP are designed to reduce total run time and deliver high volumes of sterile culture media thanks to its efficient heating system and fast cooling phase at the end of the sterilization process.

Features

- Sterilization chamber made of AISI-316L stainless steel.

- Fast cooling by water cooling coils.

- Optional compressed air system.

- Color TFT-LCD touchscreen.

- 50 programs available, adjustable by time, temperature or Fo, with the option of temperature control by flexible heart probe or direct chamber temperature. You can also keep constant the temperature at the end of cycle, adjust the dispensing temperature, the stirring speed and the counterpressure value while dispensing.

- Precise dispensing controlled by pedal or by peristaltic pump pulses for repetitive filling operations. Optional external dispensing control with the DW-MP accessory.

- Direct feed from water network or optional manual addition in the second sterilization chamber.

- Bacteriological filter for air inlet.

Advantages

- Integration in a single equipment of the preparation, sterilization, cooling and dispensing.

- Reduction in the time of the cooling phase by up to 60% compared to a traditional autoclave.

- Incorporated heart probe, sterilization controlled by Fo.

- Optional control and registry of pH, with real-time monitoring on screen.

- Powerful magnetic stirrer adjustable from 50 to 200 rpm.

- Programmable peristaltic pump.

- Easy extraction and cleaning of the media chamber thanks to integrated handle grips.

- Dispensing lines can be cleaned each time with steam pulses.

- USB port (for downloading data and charging new updates) and Ethernet port for PC connection.

- Optional integrated printer

Safety

- Safety valve and thermostat.

- Hydraulic lid blocking system while existing positive pressure in the chamber.

- Open lid sensor.

- Water level detector.